Quantitative Risk Assessment (QRA) is a technique for the evaluation and integration of hazard frequency and consequence to derive a numerical estimate of risk. In the context of facility and activity risk assessment, QRA is applied when:

- High-risk or Major Accident Hazards have been identified for a facility or operation; QRA is required to demonstrate tolerability and ALARP in support of a project or facility COMAH Report.

- There is potentially high risk of exposure to workers or the public (e.g. sour field developments, drilling activities close to populated areas, etc.).

The main objectives of a QRA are:

- Quantifying the overall risk associated with a facility or activity;

- Identifying the main contributors to the overall risk;

- Identifying measures to reduce the overall risk and analyzing their effectiveness;

- Where a number of alternative options are available, determining the relative safety and cost effectiveness of the alternatives;

- Assisting in the identification of new alternatives;

- Demonstrating compliance with risk tolerability criteria and assisting in the demonstration and achievement of ALARP to all stakeholders;

- Increasing awareness of hazards, scenario-based escalation and mitigation; and

- As an aid to communication to the workforce and third parties of their impact on, and exposure to, risk.

QRA is an integral part of ALARP process for both project activities and operations. QRA process starts at concept stage. In some cases, coarse/preliminary QRA may be carried out during concept stage especially where several options have been identified. This allows a comparison of the relative risk levels from the different options to support the decision-making process.

Comprehensive QRA is performed during FEED Stage of the project, which will be later updated during EPC (Detailed Engineering) Stage based on newly established information/data. EPCQRA also forms the basis for the operations and forms part of HSEIA dossier.

As part of COMAH/HSEIA update, QRA is reviewed to determine if significant changes to facilities, barriers in place, manning, building functionality or occupancy, etc. are observed or carried out. QRA study is updated based on these changes to ensure assessment reflect the updated changes.

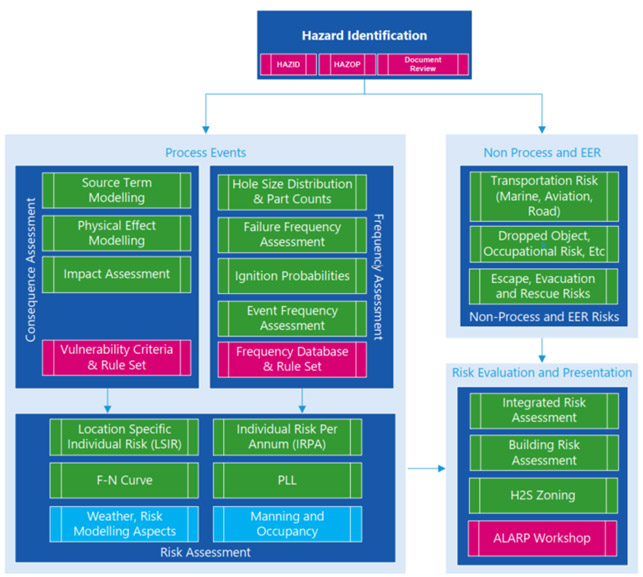

QRA follows the following flowchart, which involves the following steps:

- Identify potentially hazardous events;

- Develop incident scenarios;

- Estimate likelihood of events;

- Assess consequences; and

- Evaluate risk.

Hazard Identification

All potential Major Accident Hazards (MAH) associated with the facility or operation are taken forward for QRA. Hazard identification workshops such as HAZID, HAZOP, etc. along with document reviews are conducted to identify the MAHs associated with project facilities. Generally, two types of hazards are seen, process and non-process. Process hazards generally consist of onshore/offshore process facilities, storage facilities, piping/pipelines, drilling activities, etc. whereas non-process hazards consist of occupational hazards, transportation risk, escape and evacuation risk, ship collision, dropped object, etc.

Identification of Hazardous Inventories

When conducting QRAs, the hazardous events are defined in terms of the isolatable sections and their operating conditions. Isolatable sections are defined and bounded by the location of Emergency Shut-Down Valves (ESDVs) and Emergency Depressurization Valves (EDPVs).

Isolatable Sections (ISO) are further divided into various failure cases (FCs) based on the locations, process parameters, operating modes, etc. to capture appropriate risk profile and release events. These isolatable sections and failure cases are marked on P&IDs and attached to QRA Report.

Inventory analysis is carried out for these isolatable sections based on the static inventory based on the volume and dynamic inventory considering shutdown duration.

Identification of potential consequences

The development of the top event into a serious incident depends on the effect of safety systems, prevailing environmental conditions, actions by personnel and presence of ignition sources. QRA studies use event trees to model the chronological series of events. Event trees provide a systematic method to ensure all potential outcomes as a result of a specified top event are identified. Development of credible accident scenarios using event trees thus provides a structure to the conceptual and physical escalation scenario analysis.

Receptors

As part of the QRA, the risk to personnel is studied for all worker’s groups considering all potential plant locations, buildings and accommodations where they are likely to be present. Where, facilities are being designed or operated at a location which is closed to or next to other facilities, plant or residential facilities, these are considered as receptors and risk for these locations are studied.

Where, SIMOPS is being carried out on existing facilities or project facilities, SIMOPS locations are considered as receptors within the QRA.

Frequency Assessment

Failure frequencies and event frequencies are determined for each isolatable section/failure cases identified and associated events. Generic failure rates/ frequencies for various components are available in various historical accidental databases such as OGP, Last fire, etc. These frequencies in conjunction with parts count hole size distribution are used to determine the failure frequencies. Failure frequencies are frequency of potentially hazardous events estimated from historical databases(generic failure frequencies) combined with parts count information for associated isolatable section and failure scenarios (e.g., length of pipelines, number of valves/flanges, etc.).The leak frequency data should be apportioned by hole size by modelling the distribution of leaks across a range of hole sizes divided into bands, where each band is represented by its hole diameter. These values should be used as equivalent hole diameters when conducting the consequence and should also be used to derive the failure frequency of each leak size from each isolatable section & failure case. Part count sheets and summary of the total failure frequencies and various hole size frequencies are made available as part of the QRA Report.

Event Tree Probabilities & Event Frequencies

Event trees are used to determine the potential consequence upon the loss of containment scenario, probabilities are assigned for each event tree node. It is essential to realise that these probabilities are dependent on the events that occurred before this branch was reached and must take account of the circumstances developed by preceding branches (hence the event tree branches must be in chronological order). Typical event tree branches for a hazardous material release scenario includes:

- Immediate ignition;

- Fire and Gas detection;

- Emergency shutdown (ESD);

- Emergency depressurization (EDP);

- Delayed ignitions;

- No Ignition;

- Congestions; Etc.

The event frequency of each incident scenario i.e., consequence is derived by multiplying the failure frequency by the probabilities along the event tree branches that lead to that scenario. Note that the failure frequencies are expressed as a frequency (e.g., number of occurrences per year). The event probabilities are real probabilities (i.e., a dimensionless number between 0 and 1).

All the assumptions, curves, methodology, reference, etc. used to derive the event probabilities are documented clearly in the assumption report. Event frequencies summary for various units, deck etc.is presented in the QRA Report.

Consequences Assessment – Source Term Modelling

An important input to physical effects calculations is the source term, i.e., the rate at which hazardous material reaches the environment and the conditions of the material (e.g., temperature, composition).

For leaks from equipment, the source term refers to the mass release (or leakage) rate, calculated based on process parameters (pressure, temperature, composition), inventory and release profile A coefficient of discharge is used to account for the hole shape/type and friction loss as the material passes through the hole.

Another important aspect of the release rate calculation is its time dependence. Inventories of flammable and toxic materials can be limited by ESD systems, in which case the release rate will decline with time.

For two phase releases it is important to determine how much liquid rains out close to the point of discharge and how much is entrained by the gas. Unless the consequence modelling package can model the rain-out fraction, it is recommended to use vapour fraction to determine release inventory in terms of liquid and gas.

Another type of source term is an evaporating boiling and non-boiling liquid pool. For non-boiling pools, the evaporation rate is determined by the air movement over the spill and the size of the surface area. For boiling liquids, the evaporation rate depends on heat transfer from the substrate into the liquid and, for spills on land, will decrease as the ground cools. Spills onto water will keep a relatively constant vaporisation rate.

As part of source term modelling input information and source term modelling results are captured in the QRA Report.

Physical Effect Modelling

The term ‘effect’ refers to the possible consequences from releases of hydrocarbons and toxic gases. For example, this may be the extent of a gas cloud’s flammability or toxicity or it may be a measure of thermal radiation or explosion overpressure. Physical effects are calculated to identify which parts of the facility, community, company personnel and the public may be exposed for each potential event and the extent of that exposure. This exposure is then used to estimate the potential for further failure, escalation, impairment, injury, etc. and contribute to decisions on the need to reduce such risks.

Once the release rate has been estimated the calculation of physical effects will depend on many other factors such as wind profile, obstruction, congestions, view factors, exposure duration, etc. The physical effect modelling determines the dispersion profile and extent of various physical effect such as toxic/flammable dispersion, flash fire envelope, jet fire, pool fire, explosion effect, smoke dispersion etc.

The possible potential outcome of various ‘physical effects’ for a given release profile for each scenario under consideration is reported in the QRA Report.

Impact Assessment

Exposure to various consequence identified as part of physical effect modelling can lead to major injury or fatalities. As part of impact assessment, vulnerability of humans to the consequences of major hazard events at onshore and offshore installations, primarily those producing and/or processing hazardous fluids are established. The focus is on fatality criteria as QRAs generally address fatality risks, however injury thresholds can also identify where appropriate. The impact assessment is generally expressed in terms of lethality, which is fraction/percentage of the exposed population who would suffer fatality on exposure to a given consequence level. Typically, pro bit which is a function that relates lethality to the intensity or concentration of hazardous effect and the duration of exposure.

Generally following consequence are considered as part of impact assessment.

- Fire Scenarios (radiation levels).

- Explosions (blast overpressure).

- Toxic Gases (toxic gas exposure).

- Smoke (toxic fumes exposure).

Process Risk Assessment

Once consequence and frequency analysis are carried out, risk is estimated for hazardous fluids. Relevant details shall also be obtained from FERA (Fire & Explosion Risk Assessment). Typically process risk are presented in the form of LSIR(Location Specific Individual Risk), Individual Risk Per Annum (IRPA), Potential Loss of Life (PLL) and using F-N curve for public and for workers groups. LSIR represents the risk profile arising from process facilities whereas other indicators highlight risk to different worker groups or their representatives.

Manning and occupancy play an important role while determining IRPA, PLL and F-N Curve.

Non-Process Risk Assessment

As part of non-process risk assessment, following risks are studied for various process facilities/installations, where applicable.

- Ship Collision Risk Assessment.

- Transport Risk Assessment.

- Dropped Object Risk Assessment.

- Occupational Risk Assessment.

Dropped Object Study

Where separate Dropped Object Study is carried out, any risk to the people is considered in the QRA based on the calculated dropped object frequency and impact energy.

Occupational Risk Assessment

Occupational risk is associated with day-to-day activities (operation) of the facilities and are generally presented as FAR (Fatal Accident Rates) rates. It is required that as part of the QRA study, occupational risk is calculated for the various workers group based on the time spend in the facilities (field) over the year. Guidelines available from OGP is used to determine FAR rates.

Escape and Evacuation Risk Assessment

As minimum following escalation cases are studied as part of the QRA if identified as risk contributors to personnel.

- Potential fatalities due to escalated scenario such as BLEVE, Fireball, Boil over, Catastrophic Vessel Failure, secondary explosion or toxic releases, etc.

- Potential fatalities during evacuation such as use of lifeboat/life raft/rescue boat, impairment of muster location, impairment of TR, impairment of both the escape route etc.

Guidelines are available in OGP for determination of evacuation risk for various evacuation modes, evacuation scenario probabilities and evacuation frequency. Evacuation frequency is obtained by considering all the scenarios requiring evacuation.

Generally, escape and evacuation risk are determined for the offshore facilities, artificial islands etc. However, these aspects are reviewed for onshore QRA as applicable to ensure robustness of QRA assessment.

Integrated Risk Assessment

Once various risks such as process risk, non-process risk, escape & evacuation risk, etc. are determined, the overall risk is determined by combining Individual Risk from all these factors. For brownfield or modifications projects/QRA, existing facilities risk shall also be considered.

H2S Zoning

Locations where a H2S hazard exists are classified according to the potential threat from H2S based on the precautions needed to allow people a good chance to escape in the event of an accidental release of H2S. As part of the QRA Report, it is required that H2S zoning is carried out for facilities containing H2Sor existing H2S zoning is updated to reflect the new facilities being added.

Building Risk Assessment (BRA)

BRA is carried out to determine risk levels at each building and to identify measures to eliminate, control, and mitigate these risks. Detailed fire and explosion assessment for building is carried out as part of the FERA study. In addition to these impacts, the effect of other MAH such as toxic, smoke impairment, etc. are studied as part of the BRA. These impacts are studied for Residential, Accommodation and Industrial buildings, which are either occupied or used post emergency for EER (Escape, Evacuation and Rescue) measures. The overall summary of risk assessment is presented in QRA Report.

Simultaneous Operations (SIMOPS)

Oil and Gas operations involves many simultaneous activities where people can get exposed to significant risk. Therefore, it is important that these activities and potential SIMOPS are looked at during the development of QRA study where information is available or a separate SIMOPS QRA can be conducted.

Some of the examples of SIMOPS are listed below.

- Drilling activities conducted adjacent to live production or processing facilities.

- Construction activities conducted adjacent to live production or processing facilities.

Integrated QRA

Integrated QRA is developed for facilities which are in close vicinity of each other to ensure overall risk is considered from all the identified MAH from these facilities.

Sensitivity Analysis

Risk Assessment studies are conducted based on various assumptions made or outlined during studies. These assumptions though are based on various databases, previous history, knowledge, knowhow of the facilities, etc. needs to be tested to ensure that the risk lies within the ALARP region.

As part of QRA report, it is therefore required that sensitivity assessment is carried out for the key assumptions. The new risk results are then compared with risk acceptance criteria to confirm that the risk lies within the Tolerable or acceptable region.

Typical assumption which can undergo sensitivity test/assessment are as below:

- Duration of ESD, BDV, etc.

- SEP Values for fire.

- Congestions levels for blast assessment.

- Part Counts – Number of flanges, piping length, etc.

- Ignition Probabilities.

- Manning & Occupancy Factors.

The sensitivity results are presented in the form of LSIR, IRPA and PLL. Where large workforce or public is involved F-N Curve is also produced.

ALARP Demonstration

ALARP demonstration is required when the calculated Individual Risk Per Annum (IRPA) for various worker group lies within tolerable region as per risk acceptability criteria. The QRA provides a clear demonstration that the risk is or will be reduced to ALARP.

ALARP process starts by identification of the Major Risk Contributors to a given worker group or at a location. These major risk contributors are further drilled down to determine the top contributors to risk. Risk reduction measures are identified against these contributors to reduce the risk.

While identifying these risk reduction measures hierarchy of controls is maintained. Once these major risk contributors are identified and risk reduction measures are highlighted, an ALARP workshop is conducted to discuss and brainstorm these risk reduction measures or any additional risk reduction measures.

All applicable recommendations measures are subject to ALARP demonstration using CBA(Cost Benefit Analysis) approach.

Action Plan

The identified risk reduction measures/recommendation are documented in QRA report. All applicable recommendations which were discussed in CBA and found to be acceptable based on ALARP demonstration will be taken forward as part of action plan.