Energy, Petrochemicals and other hazardous industries are conceived by identifying & managing various hazards & risks, using established Process Hazard Analysis (PHA) that uses various tools & techniques for Hazard Identification & Risk Assessment (HIRA).

From HIRA, we identify Major Accident Hazard (MAH), which is defined as ‘hazard’ that has potential to result in a ‘Major Accident’. The ‘Major Accident’ means an ‘Occurrence’ in the operation, which leads to major, catastrophic or disastrous consequences irrespective of their likelihood, and serious consequences assigned with risk rank 3F[on Abu Dhabi National Oil Company (ADNOC) 6×6 Risk Assessment Matrix].

It is prudent to note that only ‘Process Safety hazards’ are addressed in MAH identification for which a Bowtie will be prepared, for certain reasons. i.e., Occupational Safety and Construction hazards are generally excluded. Reasons goes like this :

- Low, Medium, and High-Medium risks will be demonstrated/managed through Corporate Health, Safety & Environment Management System (HSE-MS) that means there are adequate controls in place to manage these risks.

- MAH pertaining to process safety will have to be demonstrated in ‘Control of Major Accident Hazard (COMAH)’ that means there should be specific controls required for management of MAH, which is termed as HSE Critical Equipment and System (HSECES). In addition, operational controls such as HSE Critical Tasks and Procedures required to manage the hazard will also be identified.

- Occupational Safety Hazards will be dealt through Occupational Health Risk Assessment (OHRA), which would further be demonstrated/managed through corporate HSEMS.

- Construction being the temporary phase that will be managed by controls adopted for management of constructions risks. (I will write another blog for construction risk management).

There are some misconceptions for identifying MAH using corporate Risk Assessment Matrix (RAM). I am using ADNOC 6X6 RAM for demonstration purposes; Risk 3F (High Risk), 4A to 4F (Single Fatality), 5A to 5F (Multiple Fatalities up to 10 Personnel), and 6A to 6F (Multiple Fatalities over 10 Personnel)shall be considered as MAH, which has been established in HIRA. [Numbers represent Severity and Alphabets represent Probability]. These MAHs will be modelled further using Bow-tie methodology.

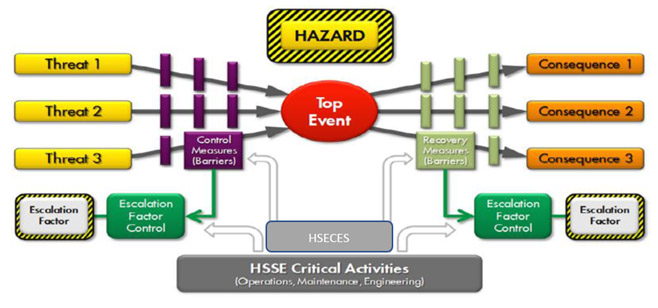

Bowtie diagram, is used to visualize ‘Process Safety hazards’ and ‘safeguards’, which illustrates identified ‘threats’, ‘consequences’, ‘safety barriers’ for each threat / consequence, ‘escalation factor’ for each ‘safety barrier’, and ‘escalation factor controls’ for each ‘escalation factor’. Confusing? Alright, let us understand these terms :

The following diagram illustrates components of bowtie, followed by its definitions :

Hazard: The potential to cause harm, including ill health and injury, damage to property, products or the environment; production losses or increased liabilities.

Top Event: A point of time which describes release or loss of control over a hazard.

Threat: A possible cause that will potentially release a hazard by producing a Top Event.

Threat Barrier (Control Measure or Safety Barrier on left hand side of Bowtie): A control that prevents the release of a hazard by acting against a Threat or Top Event.

Consequence: A potential event resulting from the release of a hazard, which directly results in loss or damage.

Consequence Barrier (Recovery Measure or Safety Barriers on right hand side of Bowtie): A control that acts on the likelihood or severity of a potential consequence. Recovery Measures mitigate a hazard’s potential to cause harm, damage, and environmental impacts.

Escalation Factor: An escalation factor is an event that can significantly impact the ability of the barrier or recovery measure to effectively manage the threat or consequence.

Escalation Factor (EF) Control: Escalation Factor Controls are measures put into place to mitigate the effects of Escalation Factors.

HSE Critical Activities: Activities that have been identified by the Hazards and Effects Management Process as vital to ensure asset integrity, prevent incidents, and/or mitigate adverse HSE effects.

HSE Critical Integrity Activities (HSECIA): Activities such as design, construction, installation, commissioning, operation, modification, repair, inspection, testing or examination associated with assuring the integrity of a HSECES. TheHSECIA are inherent part of HSECES Performance Standards as assurance activities.

HSECES Performance Standards: A statement of assurance that the HSECES will perform its function(s) as intended, shall be reliable, available and survive the effects of a major accident as and when required.

HSE Critical Activities (HSECA) Register: HSECA are those which when performed satisfactorily, contribute to the control of Major Accident Hazards. HSECA shall be managed through effective HSE Management System. HSECA Register is integral part of the HSEMS. COMAH Report shall highlight all the applicable HSECA specific to design, construction, commissioning and operation of the facilities from this register and link it to bow-ties for respective phase. Whenever, any new activity, new functionality or new hazards are introduced, HSECA Register in HSEMS shall be updated.

Bowtie diagram gives an overview of multiple plausible scenarios, in a single picture about risk that would be much more difficult to explain otherwise. This exercise therefore helps in identification of key HSECES that are in place, and HSECA that are required to be carried out for managing MAH. It is necessary that bowties are developed for each identified MAH which are grouped with similar top event that are asset and location specific. The Performance Standards (Technical Integrity Management) of each HSECES is used as means to achieve its effectiveness (Functionality, Reliability, Availability, Survivability and Inter-Dependency with other barriers).

A typical barrier acceptance criterion specifies what is deemed suitable &sufficient control of threats &mitigation of/recovery from consequences i.e., minimum of 3 independent effective barriers for threat control & recovery measures, and minimum of 2 independent effective barriers for escalation factor control. It is to be noted that for certain threats it may not be possible to have three or two independent hardware barriers or escalation factor controls. Therefore, the focus should always be on barrier effectiveness as well as the number of barriers.

The following Methodology can be adopted to carryout bowtie study :

- Identification of MAH(extracted from HAZID / HAZOP studies).

- Identification and Grouping of Top Event, to establish various bowtie diagrams (what happens when hazard is released / control is lost?).

- Populate threats on the left-hand side of bowtie (extracted from HAZID / HAZOP studies).

- Populate consequences on the right-hand side of bowtie (extracted from HAZID / HAZOP studies).

- Populate Threat Barriers corresponding to identified Threats (extracted from HAZID / HAZOP studies).

- Identify Escalation Factors on left-hand side, using brainstorming technique.

- Populate Escalation Factor Control on left-hand side, established in COMPANY.

- Populate Consequence Barriers corresponding to established Consequences (extracted from HAZID / HAZOP studies).

- Identify Escalation Factors on right-hand side, using brainstorming technique.

- Populate Escalation Factor Controlon right-hand side, established in COMPANY.

Bowtie Report is a document describing objectives and outcome of the study. The report should form the basis of a reviewer’s understanding of the completeness of the study, and the confidence that can be put in the results. The draft report should be reviewed by team members prior to a formal, timely issue.

In general, Bowtie report should contain the following sections:

- Executive Summary

- Project background

- Purpose and Objectives

- Terms of Reference specified prior to the Workshop

- List of Bowtie, grouped against top event, describing relevant threats, consequences & safeguards that are extracted from HAZID and HAZOP reports.

- Workshop Methodology

- Timing, Schedule and Venue

- Workshop Recordings

- Team Members

- Chairman’s Note

- Areas of potential weakness

- Appendices

- Terms of reference

- List of MAH

- Plant Area/Node list

- Bowties

- HAZID/HAZOP Worksheets utilized during bowtie workshop

- List of background reference documents

- All communications to and from team to subject-matter experts (SME), vendors and third parties.